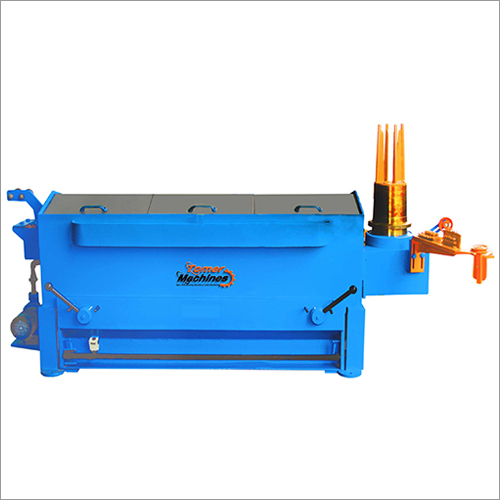

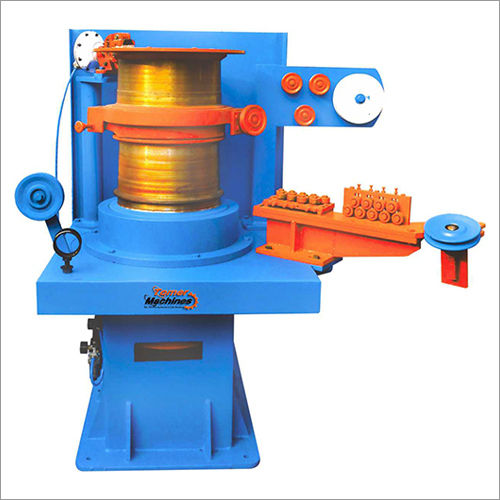

Automatic Intermediate Wire Drawing Machine

Product Details:

Automatic Intermediate Wire Drawing Machine Price And Quantity

- 500000.00 - 2500000.00 INR/Unit

- 1 Unit

Product Description

An automatic intermediate wire drawing machine, as the name implies, is used in the process of drawing metal wires. It is used in the intermediate stage of wire drawing, between the rough drawing and finishing stages. In wire drawing process, a metal wire is pulled through a series of dies, which gradually decrease in size, to reduce its diameter and increase its length. This process is repeated multiple times until the desired wire diameter is achieved. The automatic intermediate wire drawing machine is designed to handle a wide range of wire diameters and materials.

Specification

| Capacity | 300kg/hr |

| Automation Grade | Automatic |

| Voltage | 380 V |

| Frequency | 50 Hz |

| Efficiency | 99% |

| For Copper Wire | TM 312/13 | TM 312/15 | TM 312/17 | TM 312/21 |

| Inlet Size | 3.25mm | 3.00mm | 2.5mm | 2.00mm |

| Outlet Size | 1.2mm | 0.75mm | 05.mm | 0.3mm |

| For Aluminium wire | ||||

| Inlet Size | 4.00mm | 4.00mm | 4.00mm | 4.00mm |

| Outlet Size | 1.3mm | 1mm | 0.8mm | 0.55mm |

| For MS wire | | | | |

| Inlet Size | 2.00mm | 2.00mm | 2.00mm | 2.00mm |

| Outlet Size | 0.65mm | 0.6mm | 0.5mm | 0.36mm |

| For Hi-carbon wire | ||||

| Inlet Size | 2.00mm | 2.00mm | 2.00mm | 2.00mm |

| Outlet Size | 0.7mm | 0.65mm | 0.55mm | 0.4mm |

| For Stainless steel wire/ Nicron wire | ||||

| Inlet Size | 1.62mm | 1.4mm | 1.2mm | 1.00mm |

| Outlet Size | 0.55mm | 0.45mm | 0.3mm | 0.18mm |

Other Products in 'Wire Drawing Machine' category

|

TOMER MACHINES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese